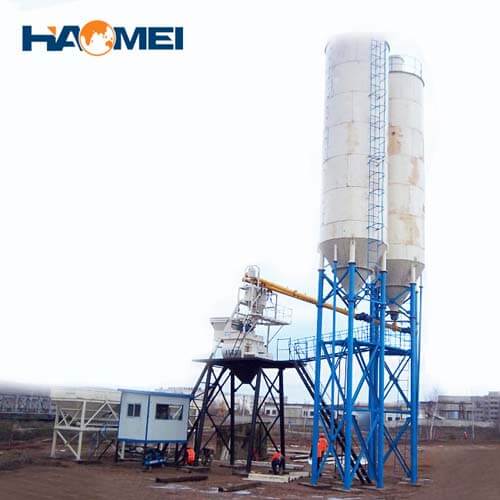

Haomei provides customized hzs50 stationary concrete batching plant made in China, welcome to inquiry if you need to concrete minxing plant in stock.

Productivity: 50m3/h

Capacity of Mixer: 1.0m3

Discharge Height: 3.8m

Feeding Type: Skip Hopper

1. Main engine of China hzs50 stationary concrete batching plant adopts JS series biaxial forced concrete mixer, which can mix even concrete in a short time.

2. The hzs50 stationary concrete batching plant in stock can produce all kinds of concrete, including seismic concrete and hard concrete. The mixing plant is a mandatory and efficient engineering equipment.

3. HZS50 concrete mixing plant is widely used in large and medium-sized construction projects, road and bridge engineering and concrete products prefabrication plant, is the ideal equipment for the production of commercial concrete.

4. The sand and gravel conveying system adopts flat belt or herge-shaped belt and is equipped with maintenance sidewalk, which is the ideal choice for construction companies to produce high-quality concrete.

5. Through the high-tech control system with the latest design concept, it can be easily operated and maintained, such as electronic weighing, computer control, digital display and so on.

China HZS50 stationary concrete batching plant:

1. Parts with high productivity and long wear.

2. Electric weighing equipment with buffer device and automatic compensation function.

3. Internationally popular modular structure.

4. Easy to install, disassemble and assemble.

5. Adapt and apply the world's most advanced technology.

6. Excellent stirring performance.

7. Main electrical components from Siemens, Germany.

JS1000 concrete mixer

1. JS series biaxial forced concrete mixer.

JS1000 double horizontal shaft concrete mixer includes mixing system, feeding system, electrical system, feeding system and discharging system.

3. It can not only work independently, but also be used together with PLD series aggregate batcher to make a simple concrete mixing plant, or as a mixer for high-end concrete mixing plant.

Cement bin of HZS50 concrete mixing plant

1. The steel cement silo is fitted with a safety valve to balance the pressure inside and outside the silo.

2. Can be equipped with a level indicator to monitor the level and quantity of materials.

3. Screw conveyor can be used to transport materials to specific locations.

4. Suitable for loading containers and exporting.

5. Perfect sealing ensures effective working performance.

The main unit of hzs50 stationary concrete batching plant in stock is the core part of the mixing station. Whether it can work normally or not is the determining part of whether the mixing station can work normally. Therefore, the maintenance and maintenance of the main unit of the mixing station is very important.

The main unit of the customized hzs50 stationary concrete batching plant made in China is mainly composed of a mixing drum and its auxiliary supporting components. The mixing drum is a loading container for concrete mixers. It is made of high-quality wear-resistant thin steel plate. In order to be able to load and unload concrete automatically, its inner wall is welded with special shaped spiral blades. When rotating, the concrete moves in the spiral direction of the blade and is mixed and stirred during the continuous lifting and turning process.

During the feeding and transportation process, the mixing drum rotates forward, and the concrete moves inward along the blade. When the material is discharged, the mixing drum reverses, and the concrete mixer unloads along the blade.

When installing a hzs50 stationary concrete batching plant made in China, details are often not valued by the user. The user's attitude towards details is incorrect. The statement that details determine success or failure is suitable for all walks of life. We will briefly introduce the installation of concrete to the majority of users here. Details that users should pay attention to when mixing stations.

1. Before installation, the user should check all the installation equipment, installation tools, check whether these equipment and workers are complete, whether there are hidden dangers, and then perform the installation procedure.

2. When installing, the most important thing is to pay attention to safety. Every employee must be equipped with the safety tools they should wear. Regardless of the hoisting of any equipment in the customized hzs50 stationary concrete batching plant, ensure that no one is nearby, especially below, and there must be professional personnel when hoisting Command; the above safety measures can be installed safely after paying attention to the installation; the installation is to randomly check the installation size and correct the deviation.

3. At the time of installation, any equipment of the concrete mixing station will be firmly connected at the waist after being lifted, and carefully checked after the connection; the flange connection surface and the flange connection surface of the discharge pipe must be coated with sealing objects during installation; Be sure to ensure the safety of the sensor.

4. The installation of the top and air valve must be checked first, and there must be no air leakage at the hose joints; every equipment in the concrete mixing station should be avoided as much as possible during the installation.

| Specification | Unit | Value |

|---|---|---|

| Productivity | m3/h | 50 |

Capacity of Mixer | m3 | 1 |

Discharge Height | m | 3.8 |

Aggregate Bin | Quantity | 3 |

Capacity of Aggregate Bin | m3 | 10 |

Max. Weighing Value of aggregate | kg | 3000 |

Max. Weighing Value of cement | kg | 600 |

Max. Weighing Value of water | kg | 400 |

Max. Weighing Value of additive | kg | 50 |

| Feeding Type | / | Skip Hopper |

| Cement Silo | / | Optional |

| Cement Screw Conveyor | / | Optional |

| Control Mode | / | Auto/Semi control |

On March 14, 2018, the Halma HZS75 concrete mixing station was successfully installed in the Philippines. Our customers are satisfied with the factory because "it's as good as before".

Read More